Temperature / Pressure Based

Quality Control

How a leading white goods supplier used Wisdom Test to detect manufacturing defects in real-time, and to improve production yield.

The Client

Tier-1 plastic parts supplier for global OEMs, producing millions of parts each year

The Challenge

Quality Inspection is manual intensive, error-prone, no quantitative explanation, the inspection queue is long

The Solution

Integrate Wisdom Test to monitor the quality inspection, oversee the process and provide predictions

The Outcome

The quality process is automatic, explainable, adaptive, continuously learning and has no human dependency

Technical Solution

Wisdom Test makes use of production / test data for training learning models and deploys them in real-time for extremely accurate quality predictions.

Overview of the production machine, identification of sensor types and locations

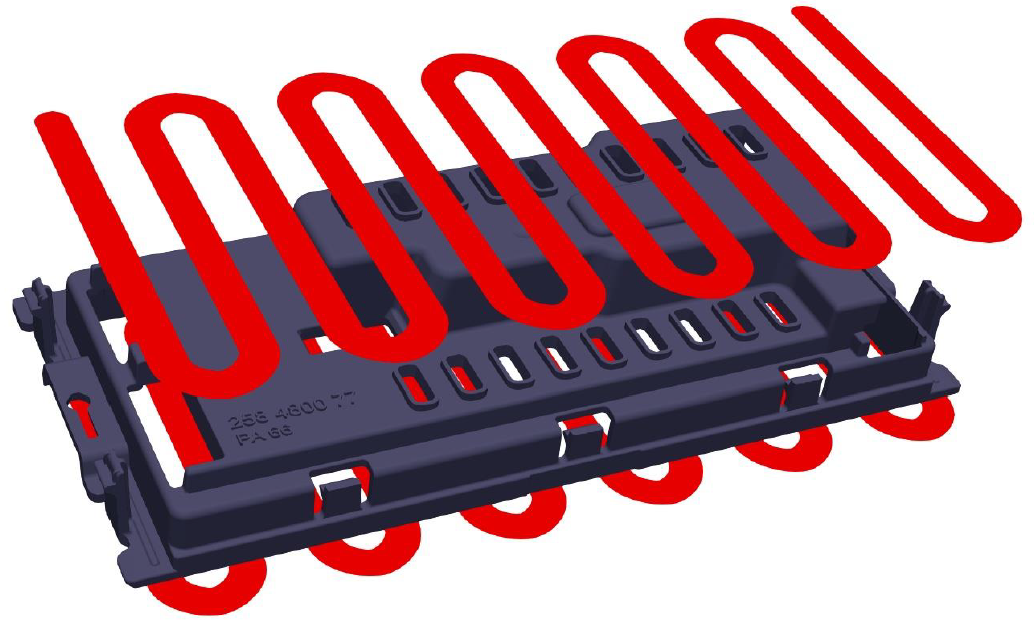

Analysis of product, mold and cooling channel setup, simulation support if needed

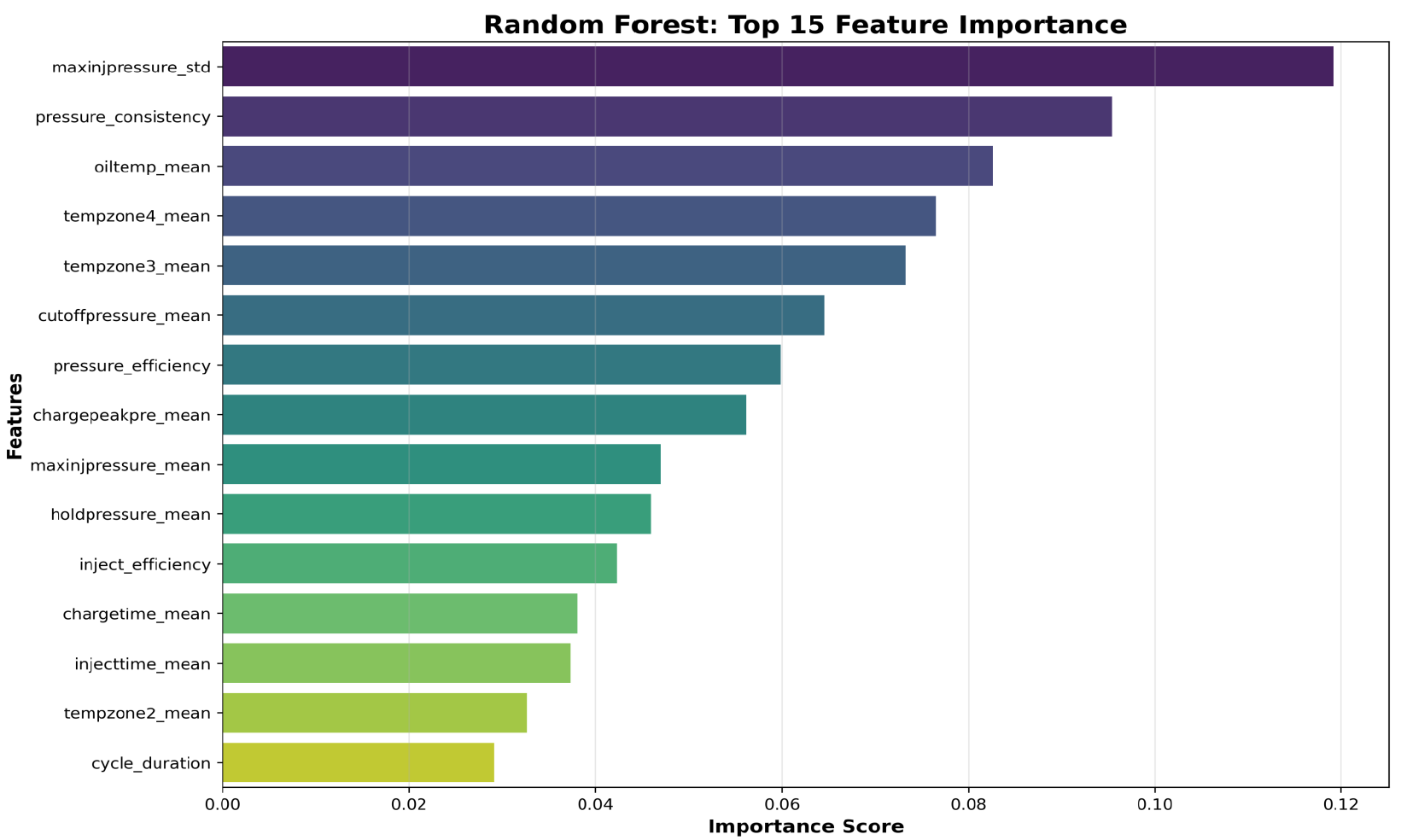

Feature importance analysis for optimizing the number of features for model training

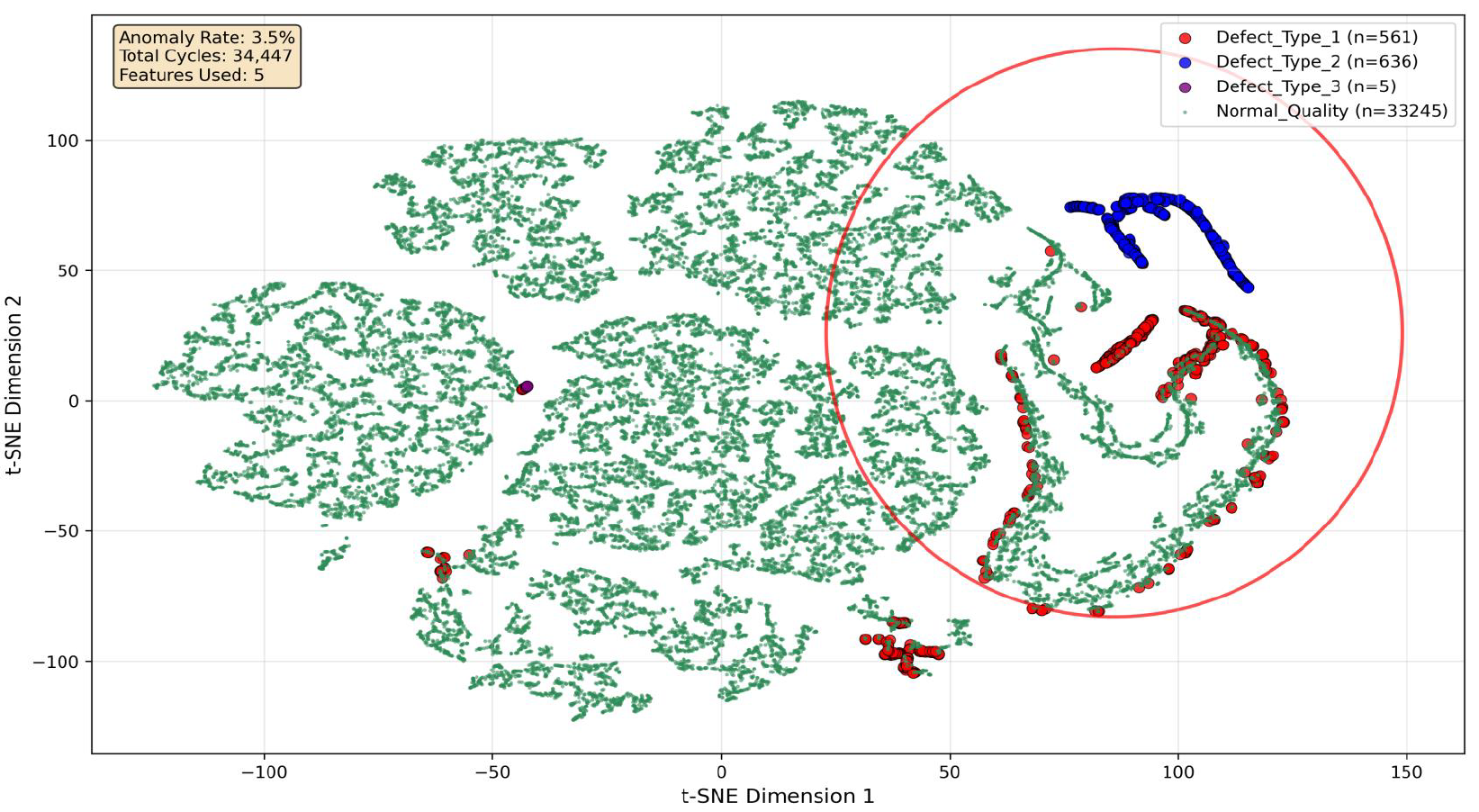

Clustering analysis and prediction supported by labeling campaigns, calibration and adaptation

Multi-Sensor Data Support

Wisdom Test supports combinations of different types of sensor data, such as pressure, temperature, noise, vibration, vision and electricity

Semi-Supervised Training

Wisdom Test uses clustering algorithms to inspect the process and makes use of minimal number of human labeled instances

Adaptive and Continuous Learning

Wisdom Test provides the framework for adaptive learning against data drift and integrates AI tools for easy of use

Benefits

Measurable Benefits in Quality Control and Cost Reduction